The Importance of Color-Coding in MRO

Maintenance, Repair, and Operations (MRO) environments rely heavily on efficiency and safety. One overlooked but essential practice is color-coding systems. Whether in power plants, factories, or large warehouses, using PVC electrical tape for color coding helps workers quickly identify circuits, cables, and components. This simple system reduces errors, enhances compliance, and improves productivity across facilities.

Why PVC Electrical Tape is the Preferred Choice

PVC electrical tape is widely adopted in industrial color-coding for several reasons:

-

🎯 High Dielectric Strength – Ensures insulation for both low- and medium-voltage applications.

-

🔧 Flexibility – Stretches easily around wires and irregular surfaces.

-

🌡 Temperature Resistance – Performs reliably in both hot and cold environments.

-

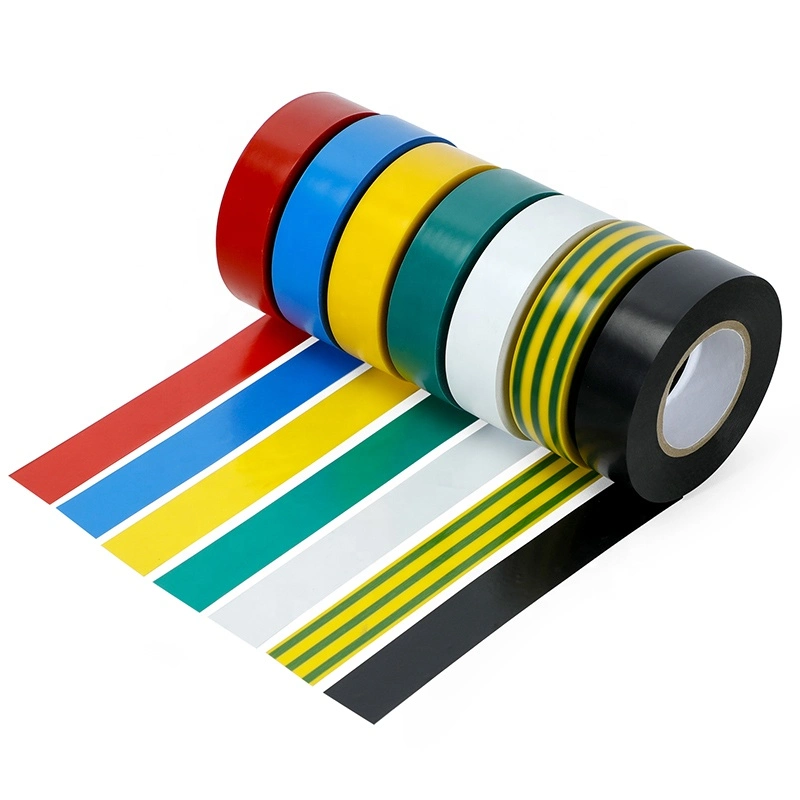

💡 Variety of Colors – Available in multiple shades for standardized coding systems.

By sourcing from professional <a href=”https://www.tape-manufacturers.com/electric-pvc-tape/”>Electric Tape Manufacturers</a>, procurement managers can access tapes that meet safety codes and come in full color ranges suitable for MRO standards.

Standard Color Codes and Applications

Different industries and regions may adopt specific coding standards, but common practices include:

-

🔴 Red – Phase A or emergency circuits

-

🟡 Yellow – Phase B or cautionary wiring

-

🔵 Blue – Phase C or low-voltage circuits

-

⚫ Black – Neutral wires

-

🟢 Green/Yellow Stripe – Grounding and earthing

-

⚪ White/Gray – Neutral in certain regional codes

Such coding helps technicians instantly recognize connections, reducing downtime and preventing accidents.

Benefits of a Color-Coding System with PVC Tape

-

⏱ Time Efficiency – Workers can identify circuits without additional labeling.

-

🛡 Enhanced Safety – Reduces the risk of incorrect connections during maintenance.

-

📦 Inventory Organization – Helps warehouses categorize tools, spare parts, and equipment.

-

🌍 Compliance – Meets international electrical color standards in multiple industries.

For global buyers, working with established <a href=”https://www.tape-manufacturers.com/”>Tape Manufacturers</a> ensures that supplied PVC tapes meet both local and international regulatory requirements.

Implementation in MRO Environments

When designing a color-coding system with PVC electrical tape, consider the following steps:

-

Define Standards – Align with IEC, NEC, or country-specific regulations.

-

Train Personnel – Educate staff on what each color represents.

-

Audit Regularly – Ensure color codes remain consistent throughout the facility.

-

Document Systems – Keep records for safety inspections and compliance audits.

-

Work with Reliable Suppliers – Secure tapes in bulk to maintain consistency across projects.

Procurement Considerations for Buyers

For distributors and importers looking to supply MRO clients:

-

MOQ Flexibility – Essential for balancing small facility needs and large industrial contracts.

-

Private Label Options – Offer branded color-coded tapes for retail markets.

-

Durability Testing – Verify performance under oil, moisture, and temperature fluctuations.

-

Packaging Solutions – Palletized cartons save space and optimize shipping costs.

Conclusion

Color-coding with PVC electrical tape is more than a visual aid—it is a proven system that supports safety, compliance, and efficiency in MRO operations. By partnering with reliable Electric Tape Manufacturers and established Tape Manufacturers, buyers can ensure consistent quality, secure supply, and confidence in every application.